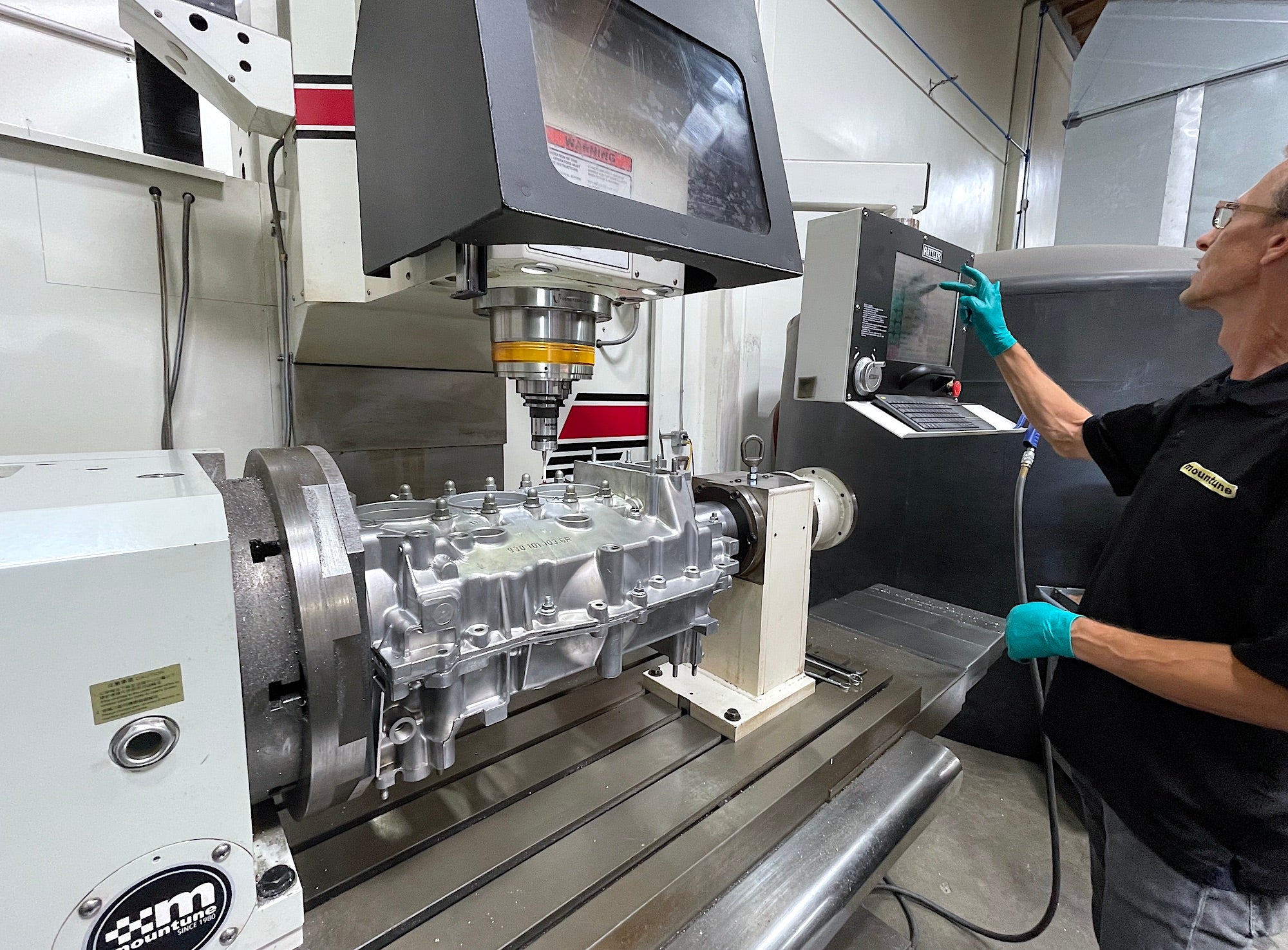

Porsche Engine Case Machining

Accurate and quality machine work is critical for any engine build and is considered as part of the foundation for maximum reliable power output. In addition to building a wide range of Porsche engines here at Mountune USA, we also provide a complete Porsche engine case machining and processing program for engine builders and restoration shops, offering a wide range of services all done in house to the highest level on the latest CNC engine machining centers Our precision machined engine cases can be found in the highest level of builds, from motorsport to complete restorations.

A Selection of Available Services

- Remove oil gallery plugs and piston oil squirt jets

- Cleaning

-

Vapor / Wet Blasting

- Align bore mains to standard (Vertical process)

- Align bore layshaft to spec

- Surface cylinder spigots to ensure flatness and parallelism

- Check cylinder spigots for ovality and flatness (CMM Process)

- Bore Case for larger Cylinders

- Bore Case for larger Cylinders w O-ring

- Replace oil gallery plugs and oil squirt jets

- Remove broken Stud (EDM Process)

- Oil Bypass Modification

- Shuffle Pin Modification

- Machine Case and Install Case Savers

- Machine Case for Larger Oil Pump

- Crack Testing

- Dynamic Balance Rotating Assembly (Crank, Rod, Pistons, Flywheel, Clutch, Pulley)

Accurate.

The main bearing housing/tunnel in older engine cases or cases that have had high duty cycles are often out of round or enlarged. Returning the case back to standard original dimensions allows the use of standard size main bearings providing accurate oil pressure and heat dissipation. We first resize the engine case by machining each case half mating surface and removing a small amount of material thereby closing up the main bearing tunnel bore and reducing the diameter below the standard dimension. This process is done on one of our CNC centers resulting in precise, flat case half mating surface providing complete sealing during final engine assembly. The case halves are then assembled using the original fasteners, torqued to original specification. The assembled case is then mounted in our Rottler F69 where we align bore the main bearing tunnel vertically.

The vertical process yields a more precise and

straighter tunnel compared to the horizontal method. We also machine the layshaft bore during the same operation. Each case is then inspected and deburred and cleaned.

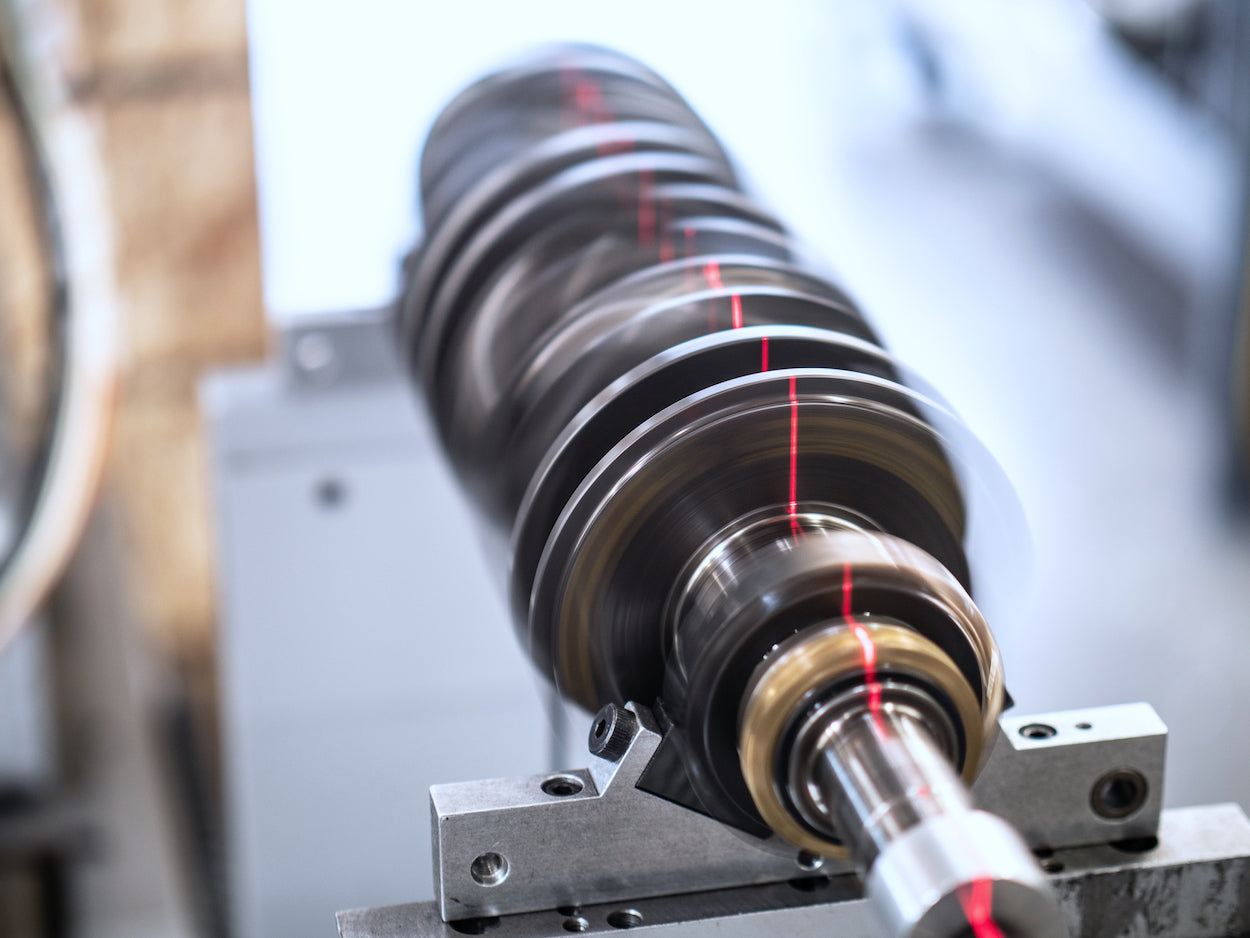

Balance.

Engine component balancing is an often-overlooked process when building an engine but essential to a smoother running assembly.

Additionally, vibration in the rotating assembly causes parasitic loss of power and can cause premature wear of components and the engine case. We balance the complete rotating assembly in house, to Formula One standards

Case Savers.

Repair and restore Porsche Magnesium cases with the latest threaded insert technology for maximum clamping load.

Most magnesium Porsche engine cases need to have the cylinder head stud threads repaired and upgraded. We machine your case and install heavy duty inserts. This upgrade should be considered for all engine rebuilds with a magnesium case. The service also includes deck resurfacing.