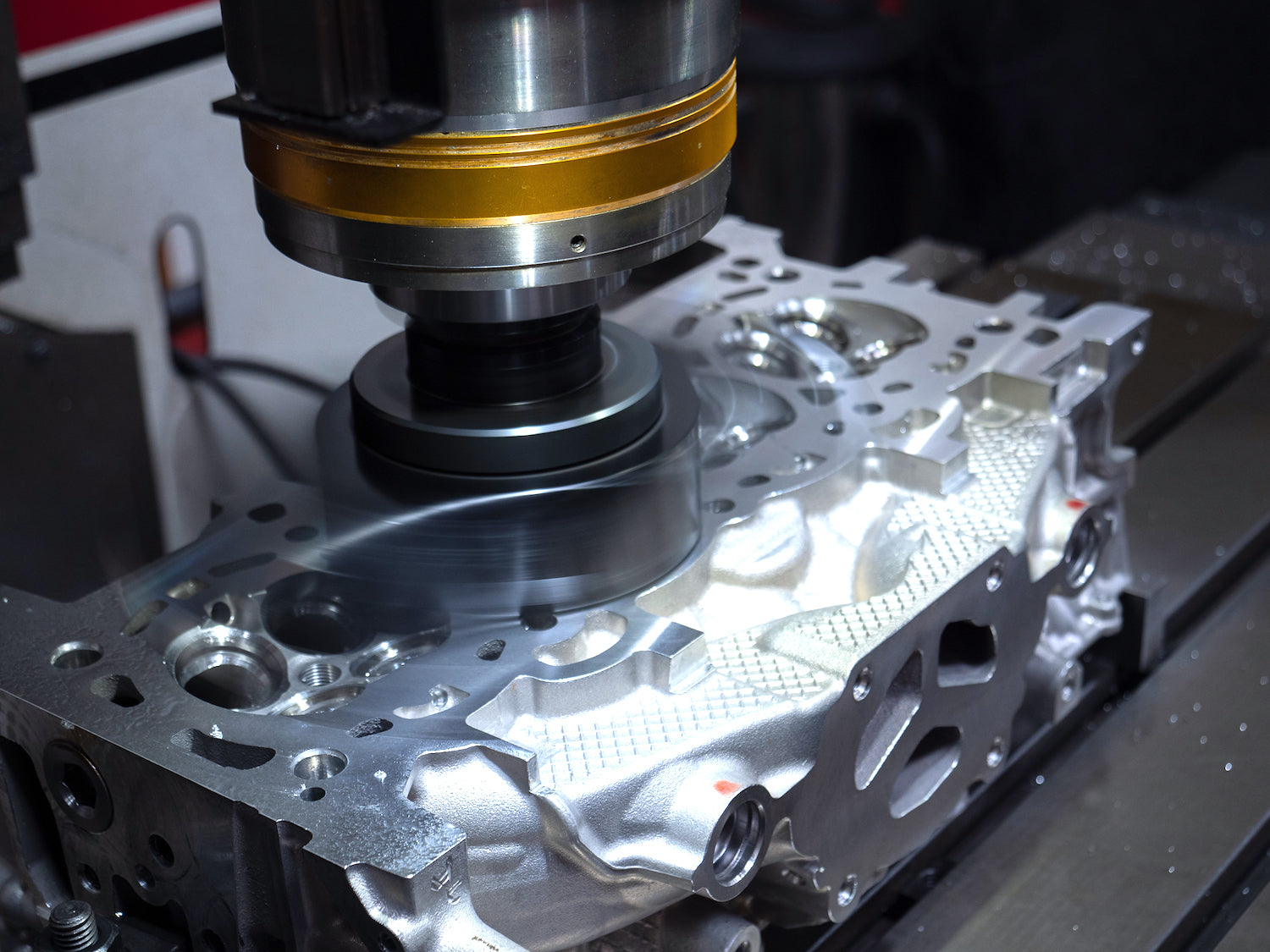

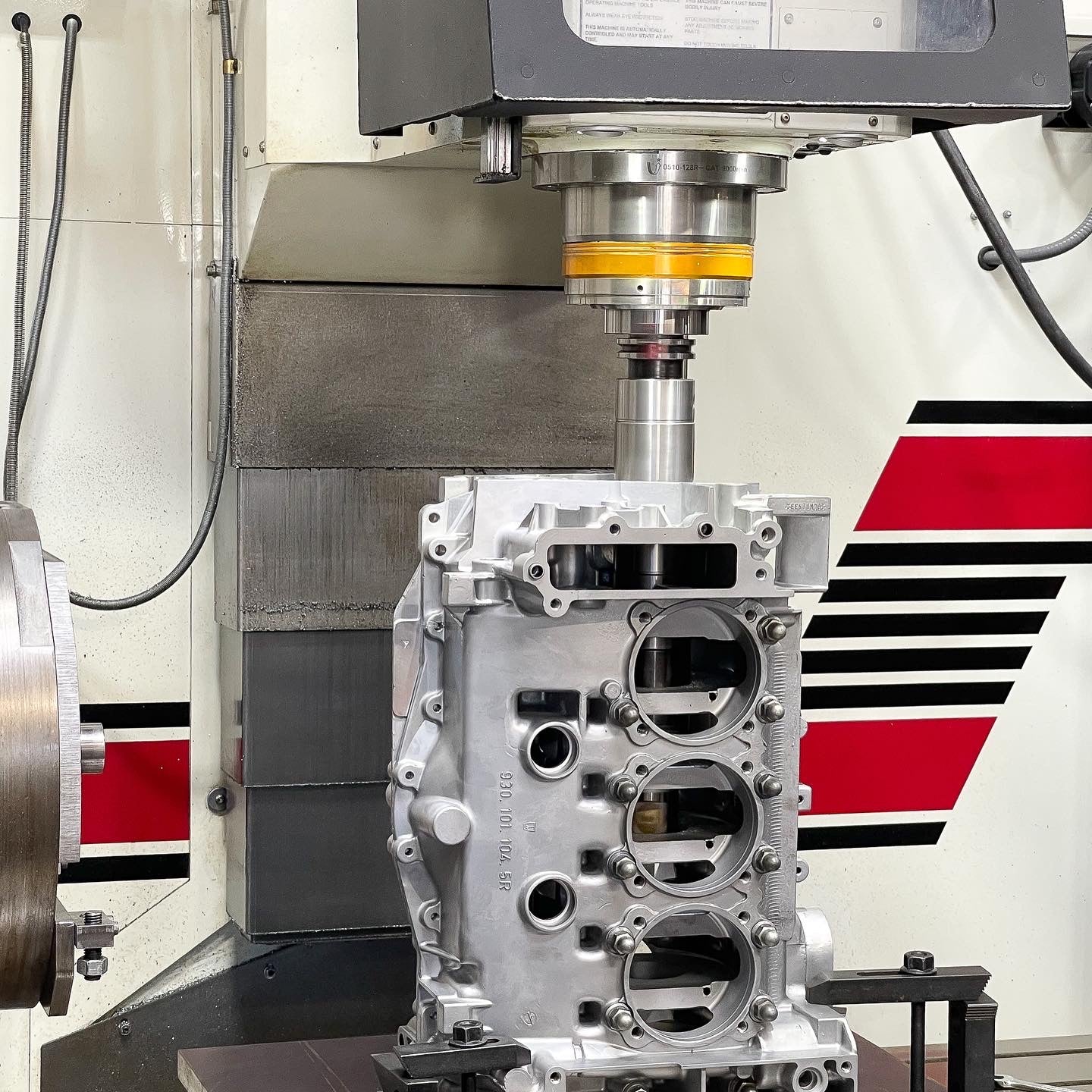

Precision Engineering at Mountune's In-House Machining Center

Welcome to Mountune's Engine Machining Services, where precision engineering meets cutting-edge technology. Our in-house machining center boasts the latest equipment, meticulously operated by our team of experts. With world-class machinery from Rottler, Serdi, and others, we take engine machining to a whole new level of excellence.

Mountune Engine Machining

CYLINDER HONING:

Using our Rottler H85A CNC Vertical Honing Machine, we achieve unmatched precision in cylinder honing. This ensures the ideal surface finish, promoting superior piston ring seating and oil retention.

LINER HONING:

Our expertise in liner honing guarantees the utmost accuracy in finishing, contributing to enhanced engine durability and longevity.

BLOCK SURFACING:

With our advanced block surfacing techniques, we create perfectly flat and smooth surfaces that optimize head gasket sealing and eliminate leaks.

BLUEPRINT BORING:

The Rottler F69A Programmable Automatic Machining Center is our tool of choice for blueprint boring, guaranteeing consistent and precise engine specifications tailored to your performance needs.

BORING & SLEEVING:

When required, we offer boring and sleeving services, accommodating oversized pistons or addressing damaged cylinders with utmost precision.

CIRCULAR INTERPOLATION:

Our circular interpolation capabilities ensure the precise and smooth machining of circular components, crucial for various engine applications.

CONNECTING ROD BORING:

We prioritize the precision of connecting rod bores, ensuring a perfect fit and alignment for critical engine components.

CYLINDER BORING:

Our cylinder boring services are pivotal for engine rebuilds, ensuring that cylinders are perfectly round and conform to the desired size.

LINE BORING:

We provide line-boring solutions to restore or improve the alignment and accuracy of essential engine components.

MULTIPURPOSE CNC (Custom Parts):

Our versatile CNC machining capabilities enable us to craft custom parts that precisely meet your engine's unique requirements.

THRUST CUTTING:

Precision thrust cutting plays a crucial role in ensuring proper clearance and alignment for engine components.

Why Choose Mountune's Engine Machining Services?

- EXPERTISE: Our team of skilled machinists and engineers possesses extensive experience and expertise in engine machining.

- CUTTING-EDGE TECHNOLOGY: Our in-house machining center is equipped with the latest CNC machinery and machining techniques, ensuring top-tier results.

- CUSTOM SOLUTIONS: We understand that each engine is unique. Our services are customized to address your engine's specific needs and performance goals.

- QUALITY ASSURANCE: Stringent quality control measures are in place to guarantee that every machined component meets or exceeds industry standards.

- RELIABILITY: Count on us for timely service and consistent performance, allowing you to stay on schedule with your project or racing season.

At Mountune, we are dedicated to pushing the boundaries of engineering excellence. Our engine machining services, backed by our cutting-edge in-house machining center and operated by a team of experts, exemplify our commitment to precision and innovation.

Contact us today to experience how Mountune's Engine Machining Services can unlock the full potential of your engine, enhancing its performance, reliability, and longevity.