Porsche Engine Case Machining

Accurate and quality machine work is critical for any engine build and is considered as part of the foundation for maximum reliable power output. In addition to building a wide range of Porsche engines here at Mountune USA, we also provide a complete Porsche engine case machining and processing program offering a wide range of services all done in house to the highest level on the latest CNC engine machining centers. We'll take a look at some of the machining services we offer for air cooled Porsche cases in this edition.

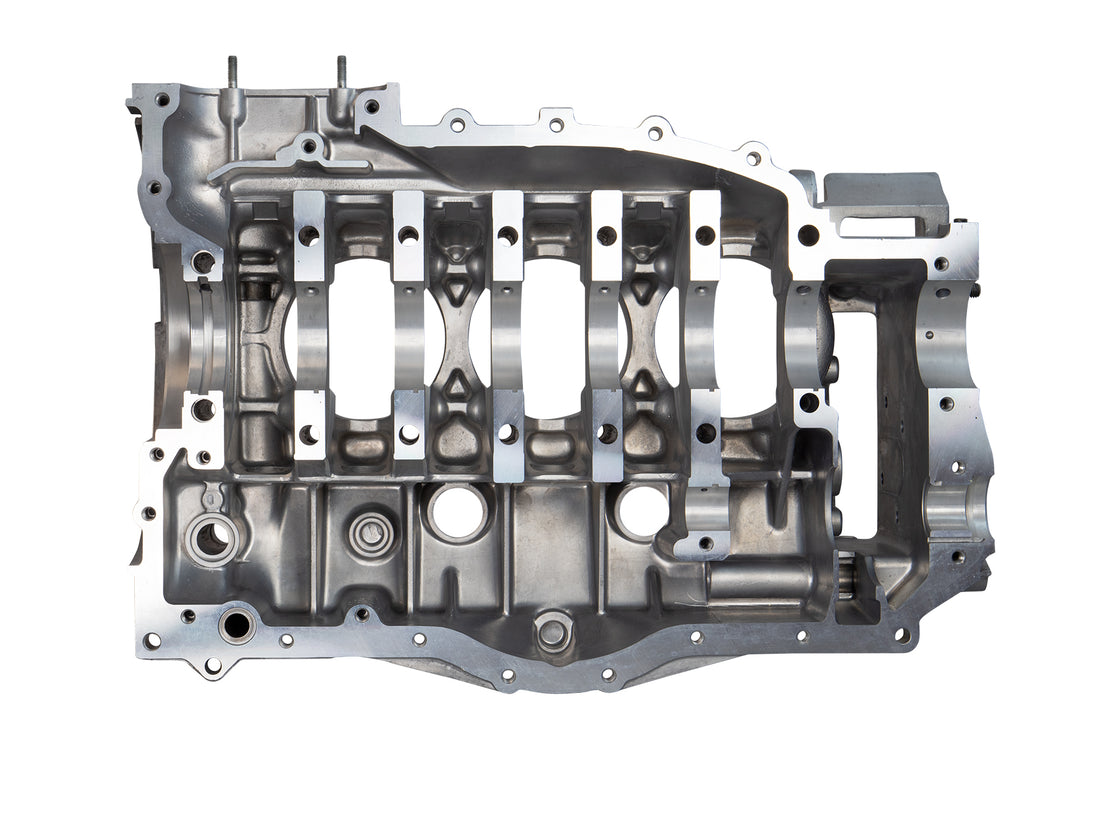

The main bearing housing/tunnel in older engine cases or cases that have had high duty cycles are often out of round or enlarged. Returning the case back to standard original dimensions allows the use of standard size main bearings providing accurate oil pressure and heat dissipation. We first resize the engine case by machining each case half mating surface and removing a small amount of material thereby closing up the main bearing tunnel bore and reducing the diameter below the standard dimension. This process is done on one of our CNC centers resulting in precise, flat case half mating surface providing complete sealing during final engine assembly.

The case halves are then assembled using the original fasteners, torqued to original specification. The assembled case is then mounted in our Rottler F69A where we align bore the main bearing tunnel vertically. The vertical process yields a more precise and straighter tunnel compared to the horizontal method. We also machine the layshaft bore during the same operation. Each case is then inspected and deburred and cleaned.

We also bore cases for larger cylinders including the O-ring groove machining process if required. The case is mounted in our Rottler F69A on the main bearing tunnel. This setup ensures the connecting rods, pistons, and cylinders will be “square” to the crankshaft. Each spigot is inspected before and after machining for flatness and ovality by CMM.

Engine component balancing is an often-overlooked process when building an engine but is essential to a smoother-running assembly. Additionally, vibration in the rotating assembly causes parasitic loss of power and can cause premature wear of components and the engine case. We balance the complete rotating assembly in-house to Formula One standards of 0.50g

From complete engine assembly and testing to critical machine work, we have you covered across the air-cooled Porsche range. Contact us for pricing or more information at info@mountuneusa.com.